上海菠萝视频网站機電科技有限公司歡迎您!

谘詢熱線:

021-31006099

取消

清空記錄

曆史記錄

清空記錄

曆史記錄

特點 Characteristics

更易潤濕,降低潤濕劑用量:

采用負壓菠萝视频APP下载+高剪切均質複合工藝,通過真空環境破除粉體(如陶瓷顆粒、納米氧化物)表麵氣膜,使液體潤濕劑快速滲透至粉體間隙,潤濕效率提升,潤濕劑用量減少。

Easier to wet, can reduce the amount of wetting agent:

Negative pressure dispersion + high shear homogeneous composite process, through the vacuum environment to breaksurface alir film of the powder (such as ceramic particles, nano oxides), so that the liquid weting agent quickly penetrate into thepowder interstices, wetting efficiency is improved, the wetting agent dosage is reduced.

杜絕空氣,能迅速脫氣、降低消泡時間和消泡劑用量Eliminate air, can quickly degas, reduce defoaming time and defoamer dosage

。1.5H的製漿時間,提高生產效率1.5H pulping time for improved productivity!

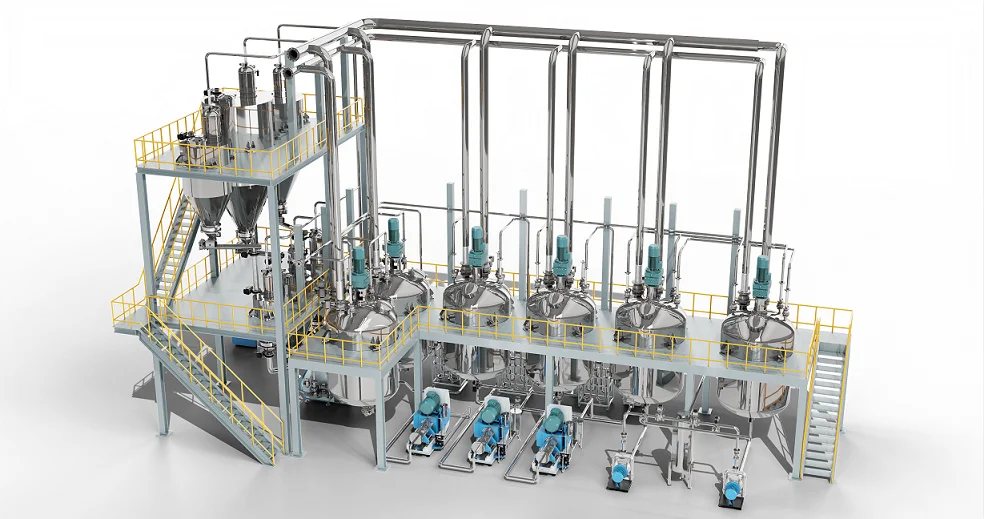

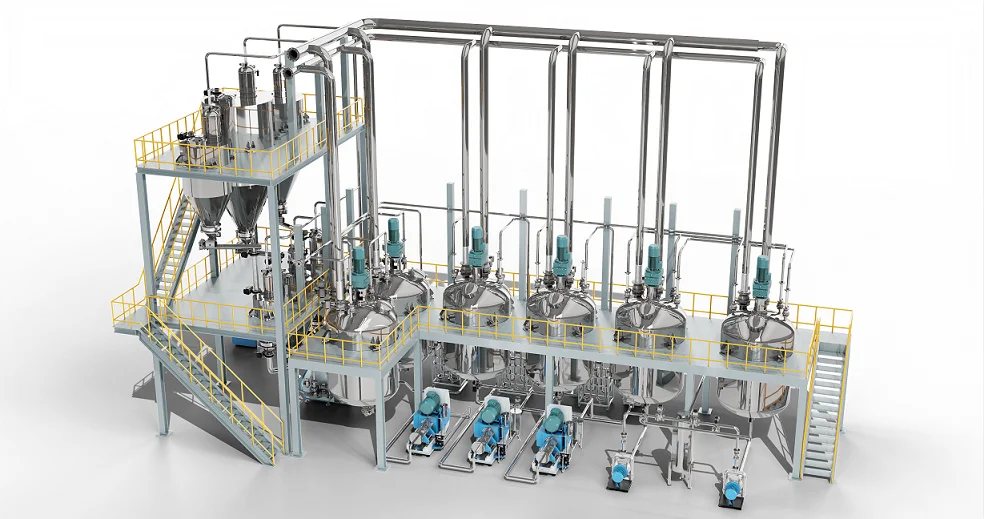

原料預處理:無塵輸送係統與恒溫儲罐聯動,實現粉液原料的**計量與瞬時混合;Raw material pre-lreatment: Dust-free conveying system is linked with constant temperalure storage tank to achieve accuratemeasurement and instant mixing of powder and liquid raw materials;

菠萝视频APP下载研磨:菠萝蜜在线网站與高壓均質機並聯運行,通過多級粒徑反饋控製,將傳統6小時的製漿周期壓縮至1.5小時,產能提升。Dispersion grinding: The sand mill and high pressure homogeniser are operated in parallel, and through multi-stage particlesize feedback control, the traditional 6-hour pulping cycle is compressed to 1.5 hours, with increased production capacity.

應用領域:

MLCC及電子陶瓷介質材料、固態電池電極與隔膜塗覆材料、 **功能性塗覆材料等行業,具體來說包含:鈦酸鋇等介質材料的納米級菠萝视频APP下载與研磨、氧化鋁等固態電池用陶瓷隔膜塗覆材料。光學膜材: 如聚酰亞胺、銫鎢青銅納米漿料,用於製備高透明、隔熱等功能薄膜等材料。

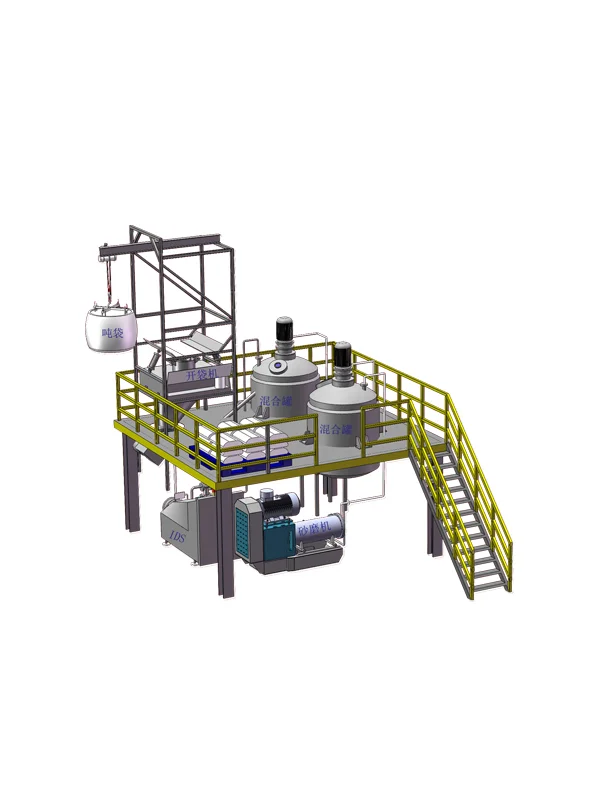

塗覆材料自動化產線

特點 Characteristics

更易潤濕,降低潤濕劑用量:

采用負壓菠萝视频APP下载+高剪切均質複合工藝,通過真空環境破除粉體(如陶瓷顆粒、納米氧化物)表麵氣膜,使液體潤濕劑快速滲透至粉體間隙,潤濕效率提升,潤濕劑用量減少。

Easier to wet, can reduce the amount of wetting agent:

Negative pressure dispersion + high shear homogeneous composite process, through the vacuum environment to breaksurface alir film of the powder (such as ceramic particles, nano oxides), so that the liquid weting agent quickly penetrate into thepowder interstices, wetting efficiency is improved, the wetting agent dosage is reduced.

杜絕空氣,能迅速脫氣、降低消泡時間和消泡劑用量Eliminate air, can quickly degas, reduce defoaming time and defoamer dosage

。1.5H的製漿時間,提高生產效率1.5H pulping time for improved productivity!

原料預處理:無塵輸送係統與恒溫儲罐聯動,實現粉液原料的**計量與瞬時混合;Raw material pre-lreatment: Dust-free conveying system is linked with constant temperalure storage tank to achieve accuratemeasurement and instant mixing of powder and liquid raw materials;

菠萝视频APP下载研磨:菠萝蜜在线网站與高壓均質機並聯運行,通過多級粒徑反饋控製,將傳統6小時的製漿周期壓縮至1.5小時,產能提升。Dispersion grinding: The sand mill and high pressure homogeniser are operated in parallel, and through multi-stage particlesize feedback control, the traditional 6-hour pulping cycle is compressed to 1.5 hours, with increased production capacity.

應用領域:

MLCC及電子陶瓷介質材料、固態電池電極與隔膜塗覆材料、 **功能性塗覆材料等行業,具體來說包含:鈦酸鋇等介質材料的納米級菠萝视频APP下载與研磨、氧化鋁等固態電池用陶瓷隔膜塗覆材料。光學膜材: 如聚酰亞胺、銫鎢青銅納米漿料,用於製備高透明、隔熱等功能薄膜等材料。

Related products

相關產品

瀏覽器自帶分享功能也很好用哦~

瀏覽器自帶分享功能也很好用哦~